The Competitive Edge of Sinseung’s Heat-Treated Scissors

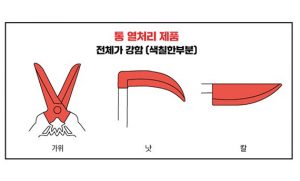

Sinseung Tools’ heat treatment process involves quenching the entire blade of scissors,sickles, and knives in a furnace, ensuring uniform hardness throughout. This allowsthe full blade to be sharpened repeatedly, maximizing usability and lifespan.

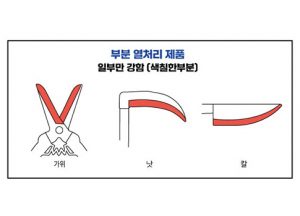

In contrast, most competitors only apply localized heat treatment (red area in Fig. 2) to the blade tip. This creates uneven hardness, preventing resharpening of the blade body once the edge wears out—shortening product life. Untreated sections are also prone to shrinkage and warping, further reducing durability

Most competitors only heat-treat the blade tip (red area), causing uneven hardness. This makes resharpening difficult once the edge wears out, shortening the tool’s life. Untreated sections also risk shrinkage and warping.

Backed by decades of expertise, Sinseung Tools ensures long-lasting quality you can trust. We remain committed to delivering superior performance through innovative heat-treatment technology.