Choosing the Right Blades Cut Depth Based on Material Type

2025-10-30Understanding Blade Cut Depth

What Blade Cut Depth Means

Blade cut depth is the distance one can cut with a blade in one pass. It depends upon how much of the blade extends out of its holder. How deep it is, of course, has a lot to do with the material you’re cutting and how thick it is. Having the proper depth makes cutting neater and easier to accomplish, without putting too much pressure on the thing or having to re-cut the same spot over and over and over again.

Why Cut Depth Matters in Material Cutting

Selecting the right blade cut depth is actually very important if you require accurate, safe, and quick results. When the blade is not deep enough, it will not cut properly. This can lead to jagged edges or not-cut-through cuts. But if it’s too deep, you might end up destroying the surface underneath or even hurting yourself. In industries such as car detailing, construction materials, or foam sculpting, having the depth exactly right reduces waste and increases your speed of work.

Factors Influencing Blade Selection

Material Thickness and Density

Different materials demand specific blade thicknesses and cutting depths due to their unique characteristics. Thicker or denser materials, such as stiff foam, leather, or vinyl flooring, demand stronger blades with higher penetration. Soft materials such as craft foam or paperboard can be cut through with thinner blades and shallower penetration depths.

Sinseung products are centered in areas like stationery, building materials, auto care, hardware, leather accessories, and gardening. The wide scope accommodates the need for selecting blades depending on material properties.

Blade Type and Sharpness

Utility knife blade fixity or snap-off and sharpness have great effects on performance at varying depths. Sharp blades reduce resistance to cutting. They make cleaner lines even when the depth is shallow. Sinseung uses good-quality materials and advanced production to ensure that blades are of high standards in cutting efficacy, longevity, and performance.

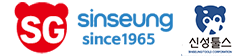

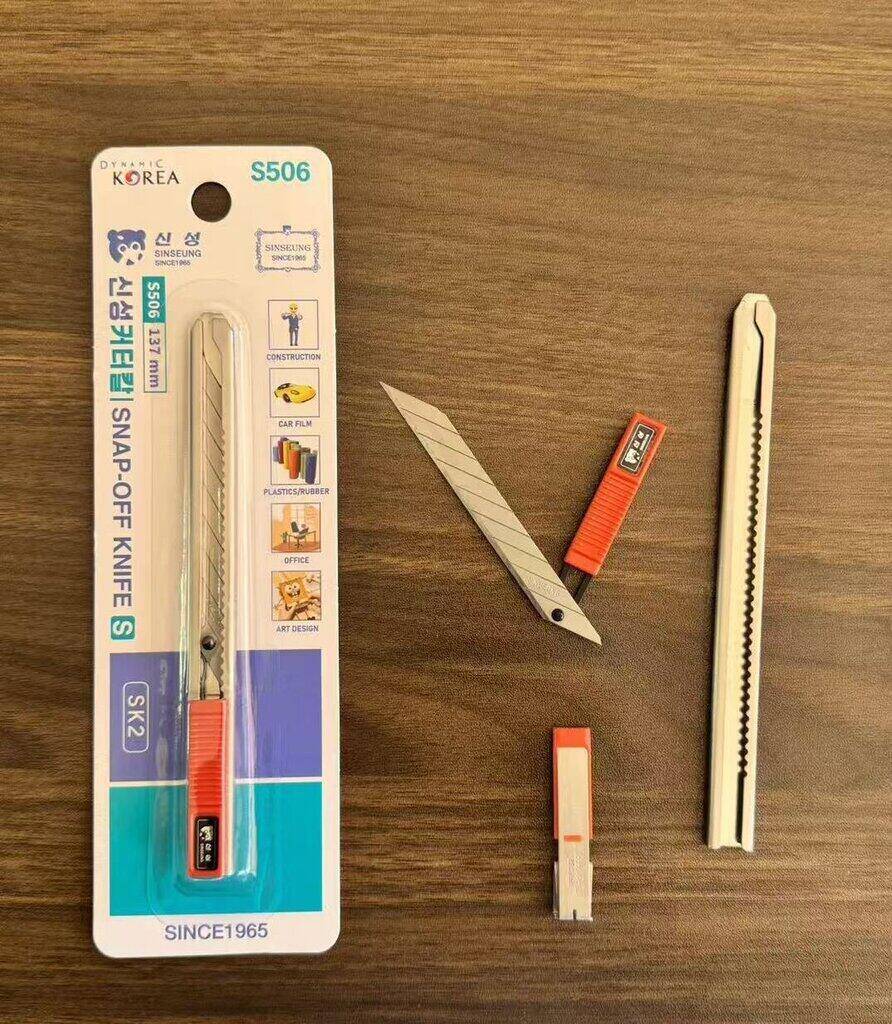

Snap-off blades such as Sinseung’s S103 (9mm), L203 (18mm), or XL401 (25mm) allow users to replace worn-out leading edges by simply snapping off dull ends. They are best applicable in layered materials where repeated edge quality is essential.

Safety Considerations When Choosing Cut Depth

Safety always comes first when deciding on cut depth. If a blade sticks out too much, it might slip or snap when you push hard. Knives that let you adjust and lock the blade give you better control over how much is out, which helps avoid accidents.

Sinseung keeps a tight watch on every step of making their blades. They do tough checks and tests to make sure each one is up to the task. This focus on trust helps keep users safe no matter what cutting job they’re doing.

Common Materials and Recommended Blade Cut Depths

Cutting Foam with a Foam Cutter Knife

Foam shows up a lot in packing, insulation, crafts, and furniture. Using a special foam cutter knife helps get smooth edges without squashing or ripping the foam apart.

Ideal Cut Depth for Soft vs. Rigid Foam

Soft foam, like polyurethane, needs only a light cut depth. Just enough to slice through without pressing the layers down. But rigid foam, such as polystyrene, needs a deeper cut with thicker utility knife blades to stop it from breaking or looking uneven.

For instance:

- Soft foam: 5–10mm cut depth using 9mm snap-off blades

- Rigid foam: 15–25mm cut depth using 18mm or 25mm utility knife blades such as Sinseung’s L203 or XL401 series

Tips for Clean and Safe Foam Cutting

When you’re using a foam cutter knife:

- Start with light cuts before going deeper.

- Always use sharp utility knife blades to keep from pulling the material.

- Keep the foam steady on a flat spot for even pressure.

- Set the blade to stick out just a tiny bit more than the foam’s thickness.

Our wins come from always chasing the best quality. This hard work makes Sinseung’s utility knives perfect for careful jobs like cutting foam.

Matching Blade Types to Material Needs

Fixed vs. Retractable Utility Knife Blades

Fixed-blade knives give solid support for tough jobs where you need deep cuts all the time. They’re great for building projects or thick plastic sheets. Meanwhile, retractable utility knives let you change the depth. These fit better for stuff that varies, like cardboard, plastic wrap, or putting up wallpaper.

Sinseung has a bunch of options, including cutter blades and utility knives. Among them, cutter blades are their top export item. Models like S506 (9mm) and L705 (18mm) come in both fixed and retractable styles to match what users need.

Specialty Blades for Precision Cuts

For detailed cutting work, like putting on car wrap film, you need special, thin blades. These cut down on drag while letting you control shallow depths easily.

Sinseung is also big on making blades for the car wrap world. These unique tools are improved with their own heat treatment tricks, which keep the edge strong without making it too stiff.

On top of that, Sinseung uses the best testing gear in the business. If they spot any bad blades, they toss out the batches before and after to keep everything top-quality.

This strict checking makes sure every special blade works just right, no matter if you’re cutting thin vinyl or thicker building films.

When choosing between fixed or retractable styles, or regular versus special blades, knowing your exact job—including the cut depth you want—is super important. It helps you get the best outcome safely and quickly.

Finding the right blade thickness for the material you’re cutting is a must for any job, whether it’s soft foam or heavy building panels. With more than 60 years of know-how in metal cutting, Sinseung is dedicated to bringing top-quality cutter blades to the world. Their wide range of products offers answers for every field, focusing on safety, accuracy, toughness, and most of all, the perfect blade cut depth for every task.

FAQ

Q:What is blade cut depth, and why is it important?

A:Blade cut depth is the distance a blade cuts in one pass. It’s crucial for achieving clean, safe, and efficient cuts, preventing jagged edges or damage to the material or surface underneath.

Q:How does material thickness affect blade cut depth?

A:Thicker or denser materials like rigid foam or leather require deeper cut depths and stronger blades, while softer materials like craft foam or paperboard need shallower depths with thinner blades.

Q:What are the recommended cut depths for cutting foam?

A:For soft foam, use a 5–10mm cut depth with 9mm snap-off blades. For rigid foam, use a 15–25mm cut depth with 18mm or 25mm utility knife blades, such as Sinseung’s L203 or XL401 series.

Q:What safety precautions should be taken when choosing the blade cut depth?

A:Ensure the blade doesn’t extend too far to avoid slips or breakage. Use adjustable, lockable knives for better control and always prioritize sharp blades to reduce resistance and enhance safety.

Q:What’s the difference between fixed and retractable utility knife blades?

A:Fixed-blade knives are ideal for consistent deep cuts in tough materials like construction panels. Retractable blades allow adjustable depths, perfect for varied materials like cardboard or wallpaper.